-

Products

New Products

- Locators with bore hole, for spring plungers

- Locators smooth, for spring plungers

- Holders for spring plungers

- Index Plungers Mini Indexes with mounting flange

- Index Plungers with locking mechanism push-lock

- Index Bolts threadless, weldable

- Spring Push Plungers with mounting flange, horizontal

- Threaded Lifting Pins self-locking, with handle

- Bedding Supports

- Flat Knurled Nuts DIN 467

- Flat Knurled Thumb Screws DIN 653

- High Knurled Nuts DIN 466

- High Knurled Thumb Screws DIN 464

- Rubber Metal Buffers waisted

- Hinges

- Hinges

- Hinges elongated on one side

- Hinges elongated on both sides

- Hinges long version

Further Information:Product Groups- Forestry Tools

- Accessories

- Promotional Boxes

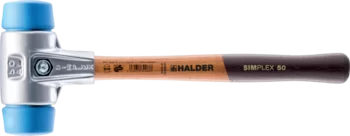

- SIMPLEX soft-face mallets, cast iron housing

- SIMPLEX soft-face mallets, reinforced cast iron housing

- SIMPLEX soft-face mallets, aluminium housing

- SIMPLEX soft-face mallets, cast iron housing, with "Stand-Up"

- SIMPLEX soft-face mallets, cast iron housing, 50:40

- SIMPLEX soft-face mallets, aluminium housing, 50:40

- SIMPLEX soft-face mallets, cast iron housing, extra short handle

- SIMPLEX soft-face mallets, cast iron housing, with "Stand-Up", extra short handle

- BASEPLEX soft-face mallets

- SIMPLEX sledge hammers, cast iron housing

- SIMPLEX sledge hammers, reinforced cast iron housing

- SIMPLEX sledge hammers, cast iron housing, with "Stand-Up"

- SUPERCRAFT soft-face mallets

- BLACKCRAFT soft-face mallet

- SECURAL soft-face mallet

- SUPERCRAFT sledge hammers

- FERROPLEX Combi Hammer

New Items- SIMPLEX soft-face mallets, 50:40 TPE-soft / TPE-mid; with cast iron housing and high-quality wooden handle

- SIMPLEX soft-face mallets, 50:40 TPE-soft / TPE-mid; with aluminium housing and high-quality wooden handle

- SIMPLEX insert, 50:40 TPE-mid, grey

- SIMPLEX Plus Box Starter Kit SIMPLEX soft-face mallet D60, rubber composition with "stand-up" / superplastic as well as one TPE-soft and one TPE-mid insert plus bottle opener

- SIMPLEX Plus Box Starter Kit SIMPLEX soft-face mallet D80, rubber composition with "stand-up" / superplastic as well as one TPE-soft and one TPE-mid insert plus bottle opener

- SIMPLEX Promotional Box Automotive SIMPLEX soft-face mallet D40, copper / soft metal plus puncher

- BLACKCRAFT Promotional Box Automotive BLACKCRAFT soft-face mallet D60 plus Magnetic Holder

- Promotional Box Dreamteam Door and Window Construction SIMPLEX soft-face mallet 50:40, TPE-soft / TPE-mid and SECURAL plus soft-face mallet

- Service

- Newsroom

- Company

- Contact

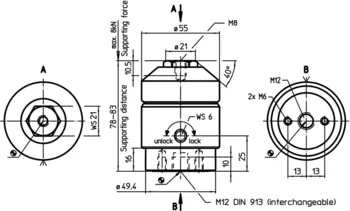

Supporting Elements

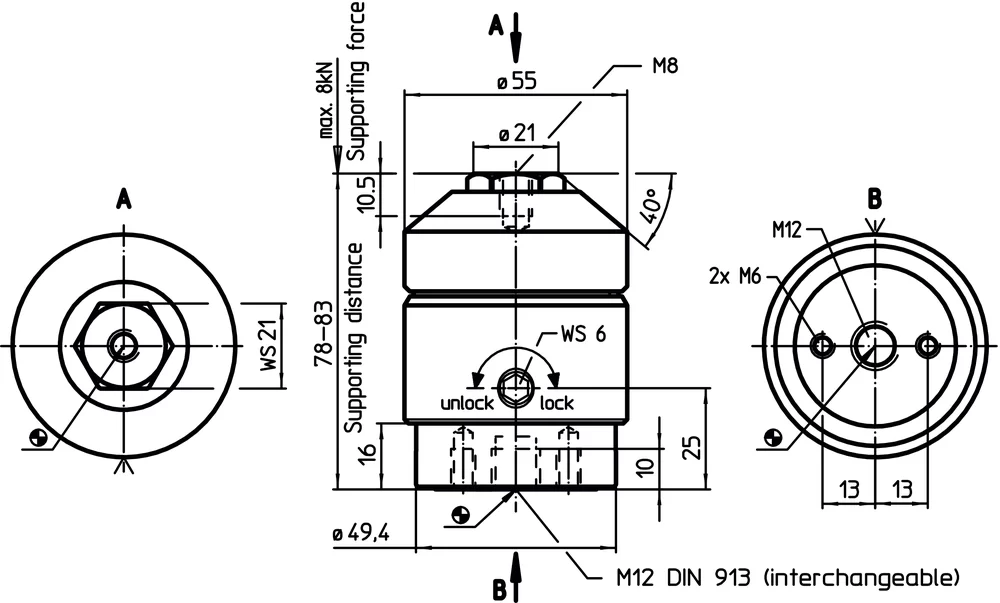

EH 23220.

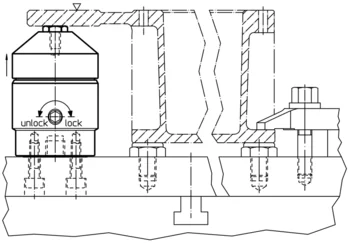

The support element is used to support overdetermined clamping points on components.

The benefits of the support element are:

- Support for unstable components

- Eliminates tool vibration during machining

- Supports ribs, beads and shackles, for reinforcement of clamped components

- Distortion-free support of raw parts

- Easy handling

Your selection resulted in 1 hits

[g]

[g]More details

Material

Housing

- Aluminium, red anodised

Body

- Case-hardened steel, nitrided, manganese phosphated and ground

Notes

For safe functioning, the thread bore M 12 must always be closed.

References

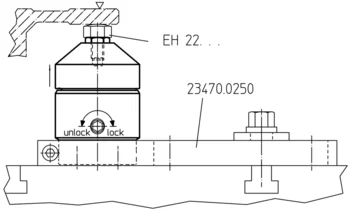

Additional flexible possibility of fitting with holding plate 23210.0740.

In the M 8 threaded pin on the support bolt various seating pins (EH 22...) can be mounted. Custom-made extensions can also be fitted.

The clamping height can be increased using height adjusting cylinders EH 23310. and with spacers EH 1107. and EH 1108.

Assembly

Fix the support element (2 x M 6 thread) onto the device. Pay attention to the operator's side!

Alternative: Dismantle the M 12 x 10 threaded pin and replace it by an M 12 x 30 threaded pin and assemble the support element with a wrench (WS 21), e.g. for T-slot mounting (no defined operator's side ensured). Threaded pin M 12 x 30 and T-nut DIN 508 M 12 x 14, quality 10, are part of the standard supply volume.

Lowering of the support element by 16 mm is possible.

Operation

By turning the clamping cam (WS 6 internal hexagon) on the outer surface of the red protective sleeve, the support pin contacts the workpiece with a slight spring load.

- By turning on (15 Nm) as far as possible (lock), total of 180°, the clamping mechanism locks the support pin without moving. The support element has been placed onto the workpiece and locked.

- If turned in the opposite direction (unlock), the clamping is released. If turned back as far as possible, i.e. total of 180° the support pin moves to the end position.

Further products

RoHS compliant

Contains lead - compliant according to exceptions 6a / 6b / 6c.

Contains SVHC substances >0,1% w/w

Contains lead - SVHC list [REACH] as of 27.06.2024.

Contains Proposition 65 substances

Lead can cause cancer and reproductive harm from exposure

https://www.P65Warnings.ca.gov/

Free from Conflict Minerals

This product does not contain any substances designated as "conflict minerals" such as tantalum, tin, gold or tungsten from the Democratic Republic of Congo or adjacent countries.

What are the use cases for the supporting element?

The supporting element can provide additional support at overdetermined clamping points, e.g. on unstable components. It helps reduce vibrations and damage to the surfaces during processing. This improves the surface quality of the workpiece and the service life of the tools dramatically.

What is the force with which the supporting elements makes contact with the workpiece?

The contact force ranges between approx. 20 and 70 N.

Is it possible to change the contact force on the workpiece?

As a customized design, the supporting element can also be manufactured with a different contact force. You are welcome to send us your request if you require such a version.

What is the difference between the supporting elements and floating clamps?

Since the surface is not covered by a clamping claw, it is possible to work on the top and the side surfaces.

Are there alternatives to the supporting element?

The bedding support may be a good and cost-effective alternative. A poor and unprofessional option is the so-called screw jack, also referred to as a “slacker”.

What to do if the supporting element fails to lock?

Here, it is essential to factor in the necessary torque (15Nm). It may not be possible to apply the necessary torque with a hex wrench and T-Handle.

What to do if the supporting element has become damaged?

Repairs are possible in most cases. To arrange for repairs, please contact our sales department.

What type of maintenance / servicing is required on the supporting element?

The supporting element is maintenance-free and does not have to be subjected to special servicing. We do, however, recommend that you regularly perform visual inspections and function tests. You should also pay attention to the oil concentration in the cooling emulsion as the functional parts on the interior may otherwise sustain corrosion.

Contacts

Contact Standard Parts Contact Workholding Systems Contact Aviation Products RepresentativeContact Form

Information Material

Information material Standard Parts Information material Workholding Systems Information material Aviation ProductsNews

Have a look to our current new parts:

Threaded Lifting Pins with handle Bedding Supports Spring Push Plungers Accessories for spring plungers Index Plungers / Index Bolts Damping Elements Hinges Knurled Nuts / Knurled Thumb Screws