-

Products

New Products

- Locators with bore hole, for spring plungers

- Locators smooth, for spring plungers

- Holders for spring plungers

- Index Plungers Mini Indexes with mounting flange

- Index Plungers with locking mechanism push-lock

- Index Bolts threadless, weldable

- Spring Push Plungers with mounting flange, horizontal

- Threaded Lifting Pins self-locking, with handle

- Bedding Supports

- Flat Knurled Nuts DIN 467

- Flat Knurled Thumb Screws DIN 653

- High Knurled Nuts DIN 466

- High Knurled Thumb Screws DIN 464

- Rubber Metal Buffers waisted

- Hinges

- Hinges

- Hinges elongated on one side

- Hinges elongated on both sides

- Hinges long version

Further Information:Product Groups- Forestry Tools

- Accessories

- Promotional Boxes

- SIMPLEX soft-face mallets, cast iron housing

- SIMPLEX soft-face mallets, reinforced cast iron housing

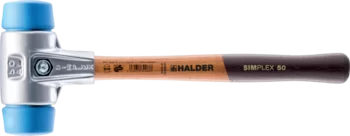

- SIMPLEX soft-face mallets, aluminium housing

- SIMPLEX soft-face mallets, cast iron housing, with "Stand-Up"

- SIMPLEX soft-face mallets, cast iron housing, 50:40

- SIMPLEX soft-face mallets, aluminium housing, 50:40

- SIMPLEX soft-face mallets, cast iron housing, extra short handle

- SIMPLEX soft-face mallets, cast iron housing, with "Stand-Up", extra short handle

- BASEPLEX soft-face mallets

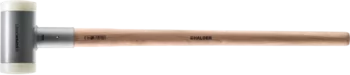

- SIMPLEX sledge hammers, cast iron housing

- SIMPLEX sledge hammers, reinforced cast iron housing

- SIMPLEX sledge hammers, cast iron housing, with "Stand-Up"

- SUPERCRAFT soft-face mallets

- BLACKCRAFT soft-face mallet

- SECURAL soft-face mallet

- SUPERCRAFT sledge hammers

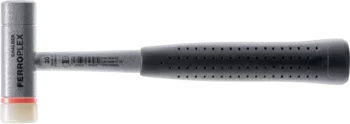

- FERROPLEX Combi Hammer

New Items- SIMPLEX soft-face mallets, 50:40 TPE-soft / TPE-mid; with cast iron housing and high-quality wooden handle

- SIMPLEX soft-face mallets, 50:40 TPE-soft / TPE-mid; with aluminium housing and high-quality wooden handle

- SIMPLEX insert, 50:40 TPE-mid, grey

- SIMPLEX Plus Box Starter Kit SIMPLEX soft-face mallet D60, rubber composition with "stand-up" / superplastic as well as one TPE-soft and one TPE-mid insert plus bottle opener

- SIMPLEX Plus Box Starter Kit SIMPLEX soft-face mallet D80, rubber composition with "stand-up" / superplastic as well as one TPE-soft and one TPE-mid insert plus bottle opener

- SIMPLEX Promotional Box Automotive SIMPLEX soft-face mallet D40, copper / soft metal plus puncher

- BLACKCRAFT Promotional Box Automotive BLACKCRAFT soft-face mallet D60 plus Magnetic Holder

- Promotional Box Dreamteam Door and Window Construction SIMPLEX soft-face mallet 50:40, TPE-soft / TPE-mid and SECURAL plus soft-face mallet

- Service

- Newsroom

- Company

- Contact

SUPERCRAFT sledge hammers

SUPERCRAFT sledge hammers

The tubular head of the SUPERCRAFT sledge hammers is filled with steel shot. The resulting effect is that the energy of the steel shot is transferred with a slight delay when the mallet's contact surface hits the workpiece. The reduced rebound allows the impact energy to be absorbed with perfect efficiency. The result is impact of exceptional magnitude. What is more, SUPERCRAFT sledge hammers allow for work with greatly improved safety, reduced strain on the joints and greater noise-dampening when compared to ordinary steel mallets.

The inserts offer outstanding impact qualities and are guaranteed to combine maximum strength with unique durability. They consist of extruded and extremely homogeneous material. Compared to injection moulded plastic inserts, they are therefore considerably more wear-resistant and durable and will never chip even in sub-zero temperatures.

The ergonomically shaped, varnished and ultra stable hickory handle is exceptionally rugged and has a vibration-dampening effect.

The handle protection sleeve acts as an overstrike protector. A secure handle-head connection is ensured by an aluminium wedge and a safety pin. The wear-resistant powder coating prevents corrosion.

Handle and inserts are replaceable