Eccentric Clamps

EH 23271.

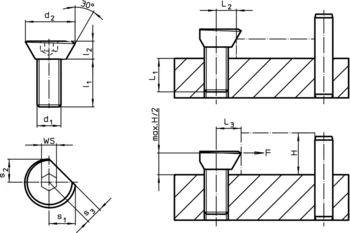

The eccentric clamp allows clamping with pull-down effect on different workpiece forms at low height.

Your selection resulted in 7 hits

More details

- d1: M3

- d2: 6.7 mm

- l1: 6 mm

- l2: 2 mm

- s1: 3.5 mm

- s2: 2.9 mm

- s3: 2.2 mm

- L1: 3 mm

- L2: 3 mm

- L3 ±0.2: 3.2 mm

- WS: 2 mm

- Clamping force max.: 0.05 kN

- Tightening torque max.: 1 Nm

- Weight: 0.6 g

- d1: M4

- d2: 8.7 mm

- l1: 8 mm

- l2: 3 mm

- s1: 4.6 mm

- s2: 4 mm

- s3: 3 mm

- L1: 4 mm

- L2: 3.5 mm

- L3 ±0.2: 4.2 mm

- WS: 2.5 mm

- Clamping force max.: 0.09 kN

- Tightening torque max.: 1.5 Nm

- Weight: 1.4 g

- d1: M5

- d2: 10.9 mm

- l1: 10 mm

- l2: 4 mm

- s1: 5.7 mm

- s2: 5 mm

- s3: 3.5 mm

- L1: 5 mm

- L2: 4.2 mm

- L3 ±0.2: 5.2 mm

- WS: 3 mm

- Clamping force max.: 0.1 kN

- Tightening torque max.: 2 Nm

- Weight: 2.8 g

- d1: M6

- d2: 13.5 mm

- l1: 12 mm

- l2: 5 mm

- s1: 7.1 mm

- s2: 6.1 mm

- s3: 4.5 mm

- L1: 6 mm

- L2: 5.4 mm

- L3 ±0.2: 6.4 mm

- WS: 4 mm

- Clamping force max.: 0.3 kN

- Tightening torque max.: 4.5 Nm

- Weight: 4.9 g

- d1: M8

- d2: 16.9 mm

- l1: 16 mm

- l2: 6 mm

- s1: 8.9 mm

- s2: 7.7 mm

- s3: 5.5 mm

- L1: 8 mm

- L2: 6.6 mm

- L3 ±0.2: 8 mm

- WS: 5 mm

- Clamping force max.: 2.7 kN

- Tightening torque max.: 20 Nm

- Weight: 11 g

- d1: M10

- d2: 20.9 mm

- l1: 20 mm

- l2: 7 mm

- s1: 11.1 mm

- s2: 9.4 mm

- s3: 6.5 mm

- L1: 10 mm

- L2: 8.3 mm

- L3 ±0.2: 9.8 mm

- WS: 6 mm

- Clamping force max.: 4 kN

- Tightening torque max.: 30 Nm

- Weight: 20 g

- d1: M12

- d2: 26.1 mm

- l1: 24 mm

- l2: 9 mm

- s1: 13.5 mm

- s2: 11.6 mm

- s3: 8 mm

- L1: 12 mm

- L2: 10.1 mm

- L3 ±0.2: 12 mm

- WS: 8 mm

- Clamping force max.: 5.4 kN

- Tightening torque max.: 44 Nm

- Weight: 35 g

Material

- Case-hardened steel, case-hardened and blue zinc-plated

Assembly

- Manufacture a thread with the corresponding distance L2 / L3 to the workpiece.

- Screw in the eccentric clamp at the necessary height and set it relative to the workpiece with its flat side.

- Insert the workpiece and tighten the clamping pin using the internal hexagon. The proper tension is achieved after approx. 1/3 turn.

The threaded hole must be lubricated on a regular basis.

The rotational movement during tightening must always be completed towards the stops in order to prevent the workpiece from turning away from the stops.

RoHS compliant

Contains lead - compliant according to exceptions 6a / 6b / 6c.

Contains SVHC substances >0,1% w/w

Contains lead - SVHC list [REACH] as of 27.06.2024.

Contains Proposition 65 substances

Lead can cause cancer and reproductive harm from exposure

https://www.P65Warnings.ca.gov/

Free from Conflict Minerals

This product does not contain any substances designated as "conflict minerals" such as tantalum, tin, gold or tungsten from the Democratic Republic of Congo or adjacent countries.