Down-Thrust Clamps moveable, size 40

EH 23310.

The moveable down-thrust clamps are used, amongst other things, when swivel movements are not possible because of the workpiece.

The clamps have the following advantages:

- Easier and quicker workpiece change by moving the clamping claws forwards or backwards.

- The clamping range in horizontal direction is between l1 min. and l1 max..

- To change the workpiece, the clamping claw can be pushed back from l1 max. by dimension l2.

- Rapid manual clamping by means of the clamping screw, the adjustable clamping lever, or the double eccentric tension lever.

- As with all down-thrust clamps, the clamping claw of this version can also be swivelled away to the left or right. The use of positioning ring 23310.0350 allows the clamping position to be fixed. Here h1 min. increases by at least 7 mm (stroke minus 7 mm).

- Compact design, therefore less space requirement when clamping.

- Easily adjustable even to large clamping heights, using the height adjusting cylinders.

As the force applied by the operator is not known for the versions with levers, the clamping force is given in the tables as a guide value. The average value was determined by tests.

Your selection resulted in 6 hits

More details

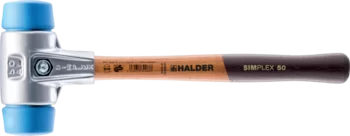

- with adjustable clamping lever with axial bearing – picture 1

- d1: 40 mm

- b1: 30 mm

- b2: 13 mm

- d2: M12

- h1: 70 mm – 90 mm

- h2: 95 mm – 115 mm

- h3: 15 mm

- h4: 20 mm

- h5: 82 mm

- l1: 38 mm – 55 mm

- l2: 30 mm

- l3: 90 mm – 107 mm

- l4: 108 mm

- Stroke: 20 mm

- Clamping force1): 6 kN

- Weight: 1400 g

- with adjustable clamping lever with axial bearing – picture 1

- d1: 40 mm

- b1: 30 mm

- b2: 13 mm

- d2: M12

- h1: 88 mm – 118 mm

- h2: 113 mm – 143 mm

- h3: 15 mm

- h4: 20 mm

- h5: 82 mm

- l1: 38 mm – 55 mm

- l2: 30 mm

- l3: 90 mm – 107 mm

- l4: 108 mm

- Stroke: 30 mm

- Clamping force1): 6 kN

- Weight: 1560 g

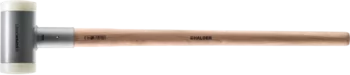

- with clamping screw – picture 2

- d1: 40 mm

- b1: 30 mm

- b2: 13 mm

- d2: M12

- h1: 70 mm – 90 mm

- h2: 95 mm – 115 mm

- h3: 15 mm

- h4: 20 mm

- h5: 13 mm

- l1: 38 mm – 55 mm

- l2: 30 mm

- l3: 90 mm – 107 mm

- Stroke: 20 mm

- Tightening torque max.: 40 Nm

- Clamping force: 10 kN

- Weight: 1075 g

- with clamping screw – picture 2

- d1: 40 mm

- b1: 30 mm

- b2: 13 mm

- d2: M12

- h1: 88 mm – 118 mm

- h2: 113 mm – 143 mm

- h3: 15 mm

- h4: 20 mm

- h5: 13 mm

- l1: 38 mm – 55 mm

- l2: 30 mm

- l3: 90 mm – 107 mm

- Stroke: 30 mm

- Tightening torque max.: 40 Nm

- Clamping force: 10 kN

- Weight: 1239 g

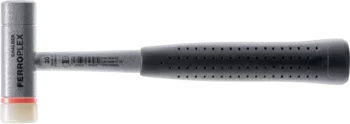

- with double eccentric levers – picture 3

- d1: 40 mm

- b1: 30 mm

- b2: 13 mm

- d2: M12

- h1: 70 mm – 90 mm

- h2: 95 mm – 115 mm

- h3: 15 mm

- h4: 20 mm

- h5: 28 mm

- l1: 38 mm – 55 mm

- l2: 30 mm

- l3: 90 mm – 107 mm

- l4: 100 mm

- Stroke: 20 mm

- Clamping force1): 4 kN

- Weight: 1396 g

- with double eccentric levers – picture 3

- d1: 40 mm

- b1: 30 mm

- b2: 13 mm

- d2: M12

- h1: 88 mm – 118 mm

- h2: 113 mm – 143 mm

- h3: 15 mm

- h4: 20 mm

- h5: 28 mm

- l1: 38 mm – 55 mm

- l2: 30 mm

- l3: 90 mm – 107 mm

- l4: 100 mm

- Stroke: 30 mm

- Clamping force1): 4 kN

- Weight: 1562 g

Material

Clamp

- Case-hardened steel, case-hardened, blackened and ground

Tension lever

- Zinc die-cast, plastic coated, orange similar to RAL 2004, matt structure

- Alloyed case-hardened steel, case-hardened, blackened

References

The clamping height can be increased by using height adjusting cylinders EH 23310. and disks EH 1107. and EH 1108. It can be reduced by employing clamping inserts, e.g. EH 22730.

Assembly

Down-thrust clamps can be attached in two ways:

- in a T-slot, using a nut for T-slots DIN 508 (EH 23010.)

- with the set screw directly in the mounting plate of, for example, a fixture

The cylinder must make contact over the whole surface.

Operation

- Push clamping claw backwards.

- Insert workpiece.

- Push clamping claw forwards.

- Adjust clamping position of clamping claw using the knurled screw.

- Secure / lock the clamping position using the knurled nut.

Further products

RoHS compliant

Contains lead - compliant according to exceptions 6a / 6b / 6c.

Contains SVHC substances >0,1% w/w

Contains lead - SVHC list [REACH] as of 27.06.2024.

Contains Proposition 65 substances

Lead can cause cancer and reproductive harm from exposure

https://www.P65Warnings.ca.gov/

Free from Conflict Minerals

This product does not contain any substances designated as "conflict minerals" such as tantalum, tin, gold or tungsten from the Democratic Republic of Congo or adjacent countries.