Floating Clamps combined clamping and locking M 16

EH 23320.

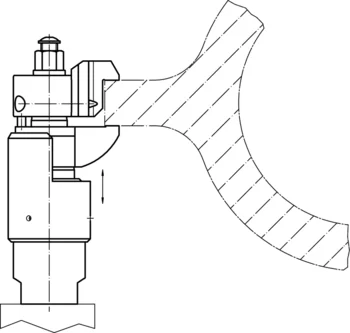

The floating clamp is used to clamp and support additional clamping points on components.

The benefits of the floating clamp are:

- Especially suitable for large workpieces with heavy machining

- Avoids vibration during the processing

- Clamps ribs, beads and shackles to reinforce clamped components

- Distortion-free clamping of raw parts

Your selection resulted in 1 hits

[g]

[g]More details

Material

Adjustable body

- Aluminium, red anodised

Body

- Case-hardened steel, nitrided, manganese phosphated and ground

Clamping jaws

- Case-hardened steel, nitrided, manganese phosphated

Assembly

- Mount the floating clamp (M 16 connection thread) onto the device with a wrench (WS 55).

- Adjust the height limit stop and the rotating area with the red sleeve and clamp with a set screw (3 x WS 3). When setting the height limit, consider tolerance of workpiece.

Operation

- Push the floating clamp downwards.

- Pivot the clamping jaws in as far as possible. The floating clamp contacts the bottom of the workpiece with a low spring load.

- Tighten the floating clamp with a hexagonal nut (WS 24) having a min. torque of 50 Nm and a maximum torque of 115 Nm. In the clamping process, the workpiece is clamped and simultaneously supported.

- Releasing is done in reverse order.

Accessories

For custom clamping situation, the standard upper clamping jaw supplied can be replaced by the exchange clamping jaws (23320.0062 / .0064 / .0066).

Further products

RoHS compliant

Contains lead - compliant according to exceptions 6a / 6b / 6c.

Contains SVHC substances >0,1% w/w

Contains lead - SVHC list [REACH] as of 27.06.2024.

Contains Proposition 65 substances

Lead can cause cancer and reproductive harm from exposure

https://www.P65Warnings.ca.gov/

Free from Conflict Minerals

This product does not contain any substances designated as "conflict minerals" such as tantalum, tin, gold or tungsten from the Democratic Republic of Congo or adjacent countries.

What are the use cases for a floating clamp?

The floating clamp prevents vibrations and the resulting chatter marks on the workpiece. It can be used as an additional clamping device, supplementing the support provided by the three standard clamping points. This will not lead to overdetermination of the component.

Which benefits arise from using floating clamps in manufacturing?

The floating clamps allow for additional clamping points during the first step of processing, preventing the formation of vibrations. This improves the surface quality of the workpiece and the service life of the tools dramatically. A secure working process is thus guaranteed.

What is the difference between the red and the blue floating clamps?

The red floating clamps clamp and lock the workpiece in a single work step. The blue floating clamps allow you to clamp and lock the workpiece separately. The latter are used predominantly on thin and unstable workpieces.

What advantage does the floating clamp hold over bedding supports and supporting elements?

Aside from supporting the workpiece, the floating clamp also clamps it from the top.

What is the benefit of a floating clamp compared to a trestle with clamps?

The spring load with which the floating clamp makes contact with the workpiece is always the same. This keeps the workpiece from bending and eliminates the need to resort to cumbersome and time-consuming clamping with the help of a dial gauge. It furthermore impresses with its compact design and effortless ease of use. Notwithstanding, the fastening on the machine table still ensures utmost stability.

Does the floating clamp provide positional repeatability?

It is possible to set the floating clamps to the required swivel range and height thanks to the colour-coded body.

What do you have to take into consideration when using the floating clamp?

You need to factor in the maximum permissible torque when clamping the workpiece. The specifications are printed on the stop sleeve and can also be found in the catalogue. You should also pay attention to the oil concentration in the cooling emulsion as the functional parts on the interior may otherwise sustain corrosion.

How much contact force does the lower clamping jaw exert on the workpiece?

The contact force of floating clamps 23320.0008 and 23320.0010 ranges from approx. 18 to 42 N. For the 23320.0012 and the 23320.0014 it lies between approx. 19 and 27 N, while the range for the 23320.0016 is approx. 73 to 99 N.

Is it possible to attach longer custom jaws at the floating clamps and, if so, what is the maximum length?

The floating clamp does allow for the attachment of custom jaws. However, their length is limited by the laws of physics and varies, first and foremost, with the strength of the material. Custom jaws with an overhanging length of 73 mm have already been realised. However, proper function cannot be guaranteed if you use custom jaws. The blue floating clamp is strongly recommended for the use of longer custom jaws on parts that are sensitive to bending. It is also vital to ensure that the mounting screws of the upper clamping jaw and of the lower clamping jaw are screwed into the housing, respectively, by 10 mm and by 9 mm. We also ask that you follow the instructions on assembly and any other information on the clamping jaws given in the catalogue.

What type of repair / maintenance is required on the floating clamp?

The floating clamp is maintenance-free and does not have to be subjected to special servicing. We do, however, recommend that you regularly perform visual inspections and function tests.

What to do of the floating clamp has become damaged?

Repairs are possible in most cases. To arrange for repairs, please contact our sales department.

Is the floating clamp limited to use inside Halder’s T-slot system V70?

The floating clamp can be used across the entire range of fixture construction. You can choose from two available size versions - M12 and M16. The flange-mounted floating clamps offer an additional fastening option. These options are listed on the datasheet of each individual floating clamp.