High-quality materials stand up to environmental impact

Scores of different versions for Airbus and Boeing available from stock

So-called steering pins are key components for the ground support at airports as they allow aircraft towing tractors to safely push the aircraft onto the runway after it has push back from the gate. With their new bypass kits, Erwin Halder KG now provides the ground crew with high-quality helpers that are sure to perform in all kinds of weather. Better yet, the experts from Achstetten-Bronnen are able to deliver the kits extra fast from stock and for a wide variety of aircraft models.

Rain or shine - aircraft take off in nearly all kinds of weather conditions. Naturally, this type of weather resistance is not possible unless all parts, tools and aids used are also fortified against a wide range of environmental impact. This applies in particular to the steering pins, which are inserted into the steering axle of the aircraft to allow for its pushback from the gate. Deactivating the aircraft’s steering hydraulics, these pins ensure that the tractor can safely move the aircraft to the runway. “This is why we use only materials of the highest quality for manufacturing the individual components that make up our bypass pin kits. This guarantees that they will stand firm against all kinds of adverse weather conditions”, explains Benedikt Uhl from the aviation sales department at Erwin Halder KG.

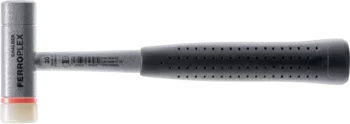

The bypass pint kits made by Halder consist of a ball lock pin - the actual steering pin, a retaining cable and a red warning streamer with the text “Remove before flight (RBF Flag). The ball lock pin along with the retaining cable and the key rings are made from stainless steel. In addition, the cable is encased with ecru-coloured plastic. This makes the components perfectly protected against all types of impact and also extra durable. In compliance with all standards, the streamers are made from nylon fibres. The red colour coating has its share in providing for perfect safety and adds the signalling effect necessary to ensure the pins are removed in time.

“At the core of our bypass pin kits are our ball lock pins. Their exceptional ease of use makes them an excellent choice for connections that need to be undone frequently - e.g. during ground support and aircraft maintenance. A press of the knob is all it takes to unlock the balls at the bottom end of the pin and allow the pin to be inserted into or removed from a bore hole. When the user releases the knob, the balls lock into place by themselves. As simple as ingenious”, rejoices Benedikt Uhl.

Halder's standard product portfolio comprises bypass pin kits for Airbus aircraft A318 through A380 and Boeing models B737 through B787. Users can pair the ball lock pins with a button handle or a T-handle. Small quantities are available immediately from stock. Better yet, Halder can also procure larger quantities quickly as they keep all components in stock. Additional kits for other types of aircraft and other manufacturers are available on request and with short delivery times.

To ensure their bypass pin kits stand up to all kinds of weather conditions, Halder manufactures all components exclusively from premium materials. The centrepieces are the ball lock pins - combined either with a button handle …

… or with a T-handle.

Downloads: